Bicycle gearbox technology has gained significant momentum in recent years. New systems are arriving on the market at an unprecedented pace, offering major benefits: improved reliability, longer durability, better chain retention, reduced maintenance, and more centralised weight distribution.

Pinion currently leads the space with its robust gearboxes, which offer broader gear ranges and smaller gear steps than traditional derailleur systems. It remains the only brand featured in DH World Cup racing.

Meanwhile, Effigear has expanded the field with two distinct gearbox models of its own.

But a new wave of innovation is rapidly emerging.

In this article, I’ll walk you through various innovative designs – ranging from derailleur-in-a-box concepts to planetary systems, belt-and-pulley configurations, spur gear mechanisms, and even a unique chain-driven gearbox featuring hinged gear clusters.

Let’s dive in.

RatioX CVT Bicycle Gearbox

Let’s start with a fully automatic gearbox with no shifter, no cables, no battery, and no electronics! The RatioX transmission is a purely mechanical device that maintains your optimal pedalling cadence regardless of speed or gradient.

This type of gear system is known as a continuously variable transmission (CVT), and that means it can have not just 10 or 12 gears, but an infinite gear ratios between two set points. The system operates much like the belt-and-pulley setups found in scooters and snowmobiles.

Gearing adjustments are handled automatically via centrifugal forces acting on weights and springs, which vary the size of the pulleys. The transmission even remains synchronised with your coasting speed, ensuring you’re always in the ideal gear when you resume pedalling.

Belt and pulley gear CVTs are known to have a fair bit of drag, making RatioX best suited for eBikes with rear hub motors. In this configuration, the motor delivers propulsion directly to the wheel, so it’s only a bit of your pedal power that will be lost to drag.

The RatioX gearbox is lighter than a Pinion (2kg), has a 360% gear range, is housed in a watertight and dustproof casing, and uses grease instead of oil, reducing maintenance needs and eliminating leaks. It’s a clever mechanical gearbox that I hope gains some popularity.

You can read more about the RatioX bicycle gearbox on the RatioX website.

Peyman CVT Gearbox

The Peyman CVT is another fully mechanical, automatic gearbox that appears to be a more affordable alternative to the RatioX system.

Initially, Peyman developed a compact, belt-driven CVT mounted at the rear wheel – an approach that was retrofittable to any bike. More recently, they’ve shifted to a larger version integrated into the crankset. This updated design offers an impressive 1000% gear range, far surpassing that of any other current gearbox.

As crank speed and torque increase, the CVT visibly shifts to a higher ratio on the pulleys – it’s a fascinating process to watch. While the original rear-mounted version lacked the ability to maintain gear position during coasting (it automatically drops to the lowest ratio), the crankset-mounted prototype may offer a solution to this limitation.

Head over to PeymanCVT.co.uk for more.

Praxis HiT Gearbox

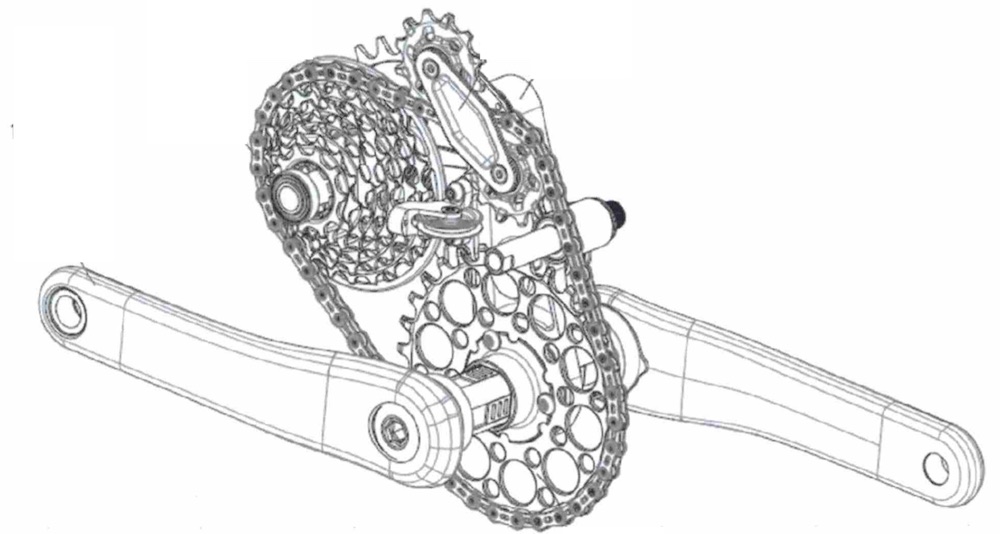

For a more lightweight and efficient gearbox solution, we turn to the Praxis HiT. Still in the prototype phase, this chain-driven gearbox incorporates hinged gear clusters – a concept enabled by Praxis’ acquisition of the Vyro 2X chainring patent.

Each gear cluster consists of a larger outer cog that folds over a smaller inner cog in four segments. This unique mechanism enables smooth shifting between gear sizes, even under high pedalling loads up to 1000 watts.

The HiT can be configured with anywhere from 4 to 16 speeds, depending on the number of clusters used, offering the potential for wide gear ranges. While the prototype uses an industrial chain, adopting a custom chain design could reduce the overall gearbox size by up to 25%.

Shifting is fully electronic and wireless, with support for both sequential and non-sequential shifting. This means you could go from the 1st gear to the 4th in one shift.

Thanks to its perfectly straight chainline, the system is expected to have low drivetrain drag. The efficiency is estimated to fall between 92% and 96%, as the system effectively combines two singlespeed drivetrains, each with losses of around 2 to 4% (eg. 0.98 × 0.98 = 0.96).

Another key advantage is its flexible integration: input and output placement can be adapted to suit various frame designs, from high-pivot mountain bikes to urban commuters.

You can learn more about the HiT bicycle gearbox on the Praxis website.

WRP Cassette In A Can

Williams Racing Products (WRP) has been teasing working prototypes of a derailleur in a box for a while.

The latest design is impressively compact, and it fits the Pinion 6-bolt mounting standard. While we can’t see inside, we can see that the input and output have now been moved to the crankshaft, and it uses two cables for shifting.

One cable is connected to an Archer D1X wireless shifter and remote, and I suspect the second cable is tensioned by a spring located inside the down tube. This spring would power one direction of the shifting, while tensioning both cables just like the spring in a derailleur.

It’s safe to assume the sprockets are very small, so don’t expect many speeds or a wide gear range on this one.

UNNO Derailleur In A Box

UNNO Bikes holds a patent for a derailleur-in-a-box, suggesting that functional prototypes may already exist.

What makes this system unique is that it doesn’t use a derailleur. Instead, the cassette itself moves side-to-side to change gears. While this is an innovative approach, it also presents packaging challenges, as the lateral movement of the cassette must be accommodated within the confines of the gearbox.

Nuseti Inner Drive System

Stepping away from traditional chains, we have a drivetrain entirely housed within the frame.

Nuseti has spent over a decade developing its Inner Drive System – a fully enclosed drivetrain designed for minimal maintenance, easy cleaning, and outstanding durability. With all gear components sealed inside the frame, they’re fully protected from the elements. This design also simplifies rear wheel removal, since the drivetrain remains mounted to the bike.

At its core is a proprietary 16-speed planetary gearbox located at the crankset, developed in collaboration with gearbox software specialists KISSsoft. It offers a wide 573% gear range with evenly spaced steps for consistent pedalling performance.

One of the standout features is the fully enclosed Gates Carbon Drive belt, integrated inside the chainstay. Belts are perfect for this setup: they don’t stretch, require no lubrication, operate quietly, and can last up to 30,000km – especially when shielded from dirt and moisture.

Shifting is controlled via levers on either side of the handlebar, similar to SRAM’s road and gravel systems. The current prototype is built into a full-carbon monocoque frame, with total bike weight projected between 10–12kg (22–26lb), making it one of the lightest gearbox-equipped bikes available.

Shimano Planetary Bicycle Gearbox

Shimano has recently filed a new gearbox patent that represents a major shift from its earlier derailleur-in-a-box concepts. This latest design introduces both eBike and non-eBike designs.

The internal layout reveals a large spur gear connected to a multi-stage planetary gear set featuring stepped gears. While the patent doesn’t specify the exact number of gears, it does outline gear ratio ranges between 250% and 444%.

One standout element is the offset between the crank and sprocket. This configuration could allow the gearbox to be rotated vertically, similar to the Effigear Original, giving full-suspension frame designers greater flexibility in tuning anti-squat performance.

Fox Factory Gearbox

And finally, there’s Fox Factory (renowned for their suspension systems), which has secured a patent for a gearbox design that tackles one of the biggest hurdles in gearbox tech: shifting under load.

Most gearboxes require a reduction in pedal force to shift gears, as attempting to shift while any pawls are engaged can cause damage. Fox’s solution involves a shift ring that automatically moves the pawls into a disengaged state under torque, allowing smooth gear changes even when the drivetrain is under load.

Although the patent doesn’t specify the number of gears, the compact layout resembles the Effigear Mimic, suggesting it could accommodate up to nine gears within its design.

Summary

I hope these new gearboxes sparked some excitement about the rapidly evolving world of drivetrain technology.

Let me know which design you like best and why. Also, if you come across any prototype gearbox drivetrains in development, feel free to share them in the YouTube comments. I’d love to explore and analyse their designs in future videos.